Principles of LPRL Technology

LPRL

IR

stealth coating technology alters the thermal emissivity of a host.

Emissivity is defined as the ratio of radiant energy emitted by a body to

the radiant energy emitted by a black body at the same temperature. Formally,

![]()

where

e

is the emissivity, and Wgray body (Wblack body)

is the total radiant energy emitted by a gray body (black body) at a given

temperature. Hence an emissivity of

unity corresponds to a perfect black body, while an emissivity of 0 corresponds

to a completely non-emissive material.

The

radiation emitted by a black body is described by Planck’s Law and is shown

below in Figure 1 for several temperatures.

As the temperature increases, the peak emission wavelength shifts towards

the blue. This is known a Wien’s

law, and is described by the formula

![]()

where

lmax

is the wavelength in microns

of the peak of the radiant emittance and T is the temperature in Kelvin.

Figure 1:

Spectral radiant emittance from a black body at several temperatures.

LPRL IR stealth

coatings exploit LPRL’s patented selective emissivity technology, which enable

our coatings to shift the energy of the emitted radiation outside the detectable

band.

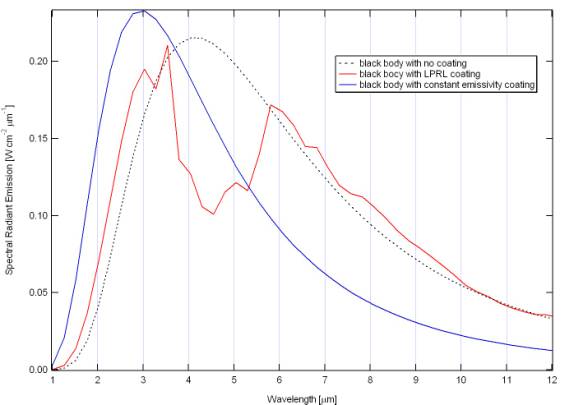

For example, we show below the spectral radiant emittance from a body at 700 K (427 C) that is coated with a coating of LPRL low observable paint, and the same thing coated with a broad-band metallic-based low observable paint. Note that the emittance from the LPRL coated object is reduced in band II (3 to 5 mm), and is increased outside of this band (red curve is above black dashed curve outside of band II). The same object coated with a metallic-based low emissivity coating also emits less in band II (although not to the extent of the LPRL coating), but does not shift the emittance into the atmospheric absorption band (5 to 10 mm) as does the LPRL coating. In addition, since the broad-band coating acts as a thermal insulator, the temperature of the underlying object is increased to a much greater extent than for the LPRL coating.

Figure 3:

The spectral radiant emittance from a 1 cm black body cube heated to 700

K (427 C, dashed curve), the same cube coated with an LPRL low emissivity

coating (red curve), and coated with a broad-band metallic-based low emissivity

coating (blue curve).

The LPRL coating not only render IR detection more difficult by reducing the emission in band II, but, by perturbing the spectral distribution of the emitted radiation, also deceives thermal images that rely on reference spectra to arrive at the brightness temperature of an object. In addition, being non-metallic in nature, LPRL low emissivity coatings are also compatible with radar absorbing materials (RAM), and may therefore be used in multipurpose coatings (IR/RAM), which we describe in more detail below Finally, LPRL coatings minimize the thermal penalty of low emissivity coatings.

Combined Infrared and Radar Stealth

To this point, we

have discussed IR stealth technology as separate from radar stealth technology.

However, in the near future coatings will have to perform both functions

simultaneously in order to counter the threat of dual mode missile guidance

systems such as the MICA air-to-air missile that equips, among others, the

Mirage 2000-5.

In general, a unit’s coating will need to satisfy the requirements of

the missions for which it was designed.

For example, ground-support aircraft face very different threats than

tanks or ships or aircraft designed with air superiority assumed, and the

coatings of each will be different.

Certain zones need only an IR stealth or RAM coating, while other zones

require a combined IR/RAM stealth coating.

As discussed above in

the brief review of stealth technologies, it is difficult to combine IR and

radar stealth because current IR stealth materials are based on electrically conductive

elements, which are highly reflective in the radar domain.

Hence the dielectric nature of the LPRL IR stealth coatings proves

advantageous for creating combined IR/RAM coatings because the active elements that

provide IR stealth do not perturb the RAM characteristics.

On the contrary, LPRL IR stealth coatings actually provide a modest

amount of radar furtivity.

To demonstrate this

effect, we show in Table 2 below

the mean attenuation coefficient for a 150

mm

thick LPRL IR stealth coating.

While the magnitudes of these attenuation coefficients obviously are not

sufficient to provide the primary radar stealth properties of a vehicle, they do

demonstrate the compatibility of LPRL IR coatings with radar cross-section (RCS)

reduction schemes.

| Polarization | Incident Angle | Mean Attenuation Coefficient [dB] at given frequency | ||

| 7.5 - 12.5 GHz | 28.5 - 40.5 GHz | 75 - 100 GHz | ||

| Horizontal | Normal | 0.03 | 0.3 | 0.026 |

| Horizontal | 5º |

1 | 1.7 | 2.28 |

| Horizontal | 10º |

4.75 | 6.5 | 6.25 |

| Vertical | Normal | 0.035 | 0.025 | 0.05 |

| Vertical | 5º |

2.0 | 1.9 | 2.0 |

| Vertical | 10º |

7.5 | 7.0 | 6.5 |

Table 1 – The

mean attenuation in the GHz range of a 150

mm thick

LPRL IR stealth coating.

To provide true multipurpose coatings (combined IR and radar stealth coatings) LPRL IR low observable coatings must be combined with radar absorbing materials, using either a multilayer or homogeneous approach. The schematic diagram below gives the essence of these two approaches.

Figure 3: A schematic diagram showing two different approaches for making dual-purpose coatings (IR and radar stealth).

The multilayer architecture consists of applying sequential layers of different coatings. In this approach, the outer layer typically provides the IR stealth properties, without perturbing the RCS of the host. The inner layer is designed to reduce the RCS.

In the homogenous

material the active dopants that provide IR or radar stealth are blended

together in precise stoichiometric ratios that are varied depending on the

application (aircraft, ship, tank…) and/or mission.